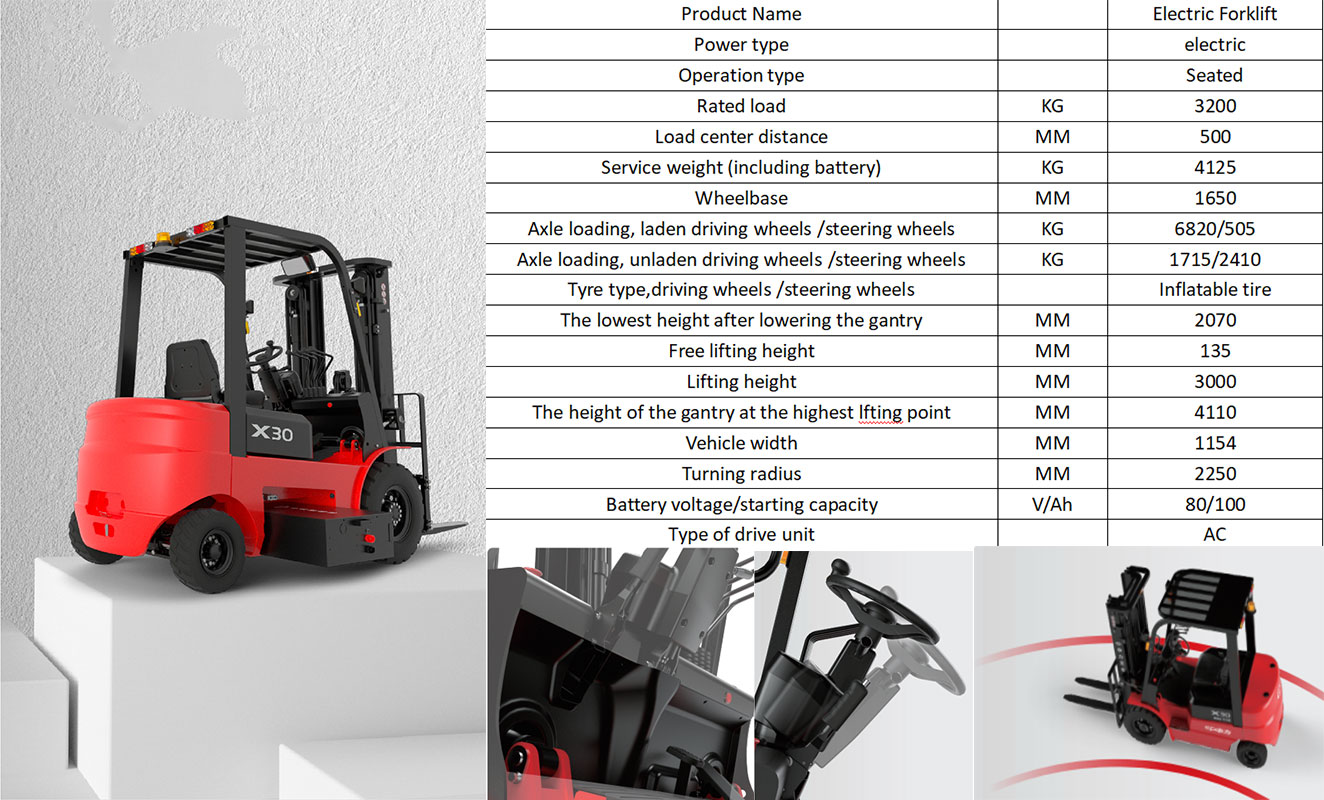

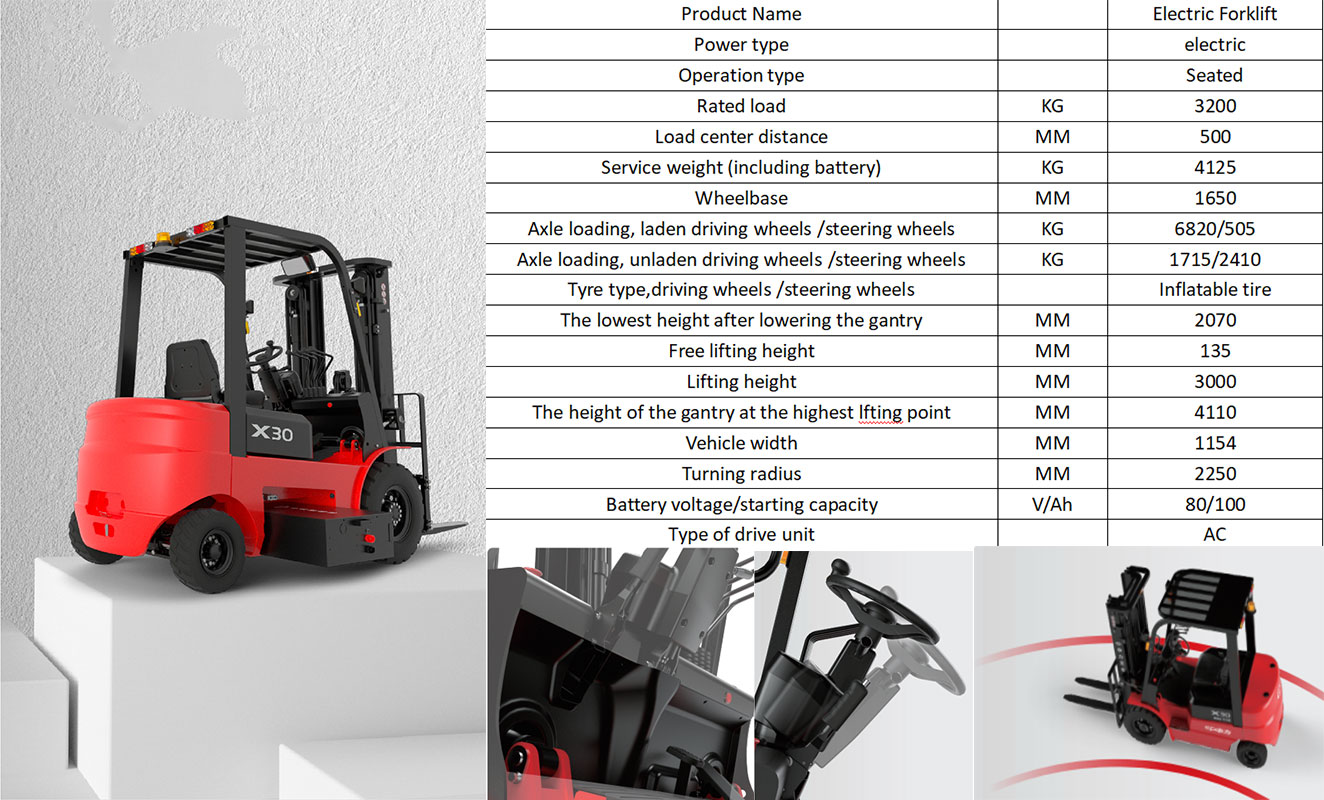

Product Parameter

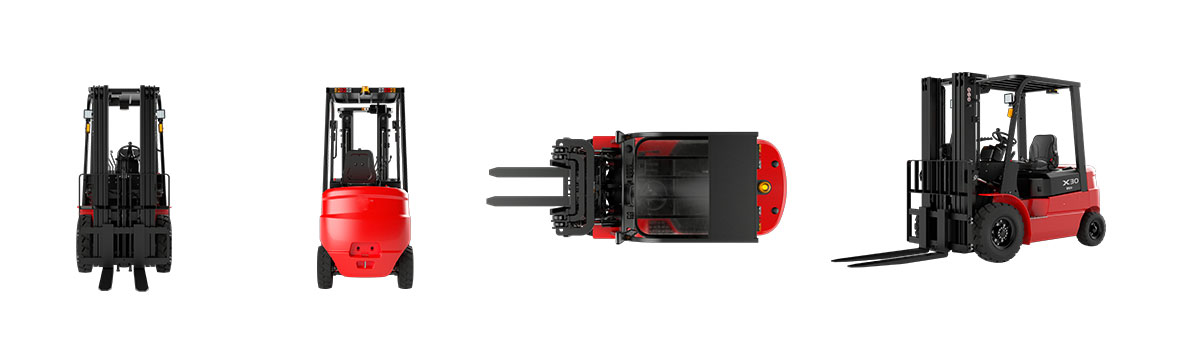

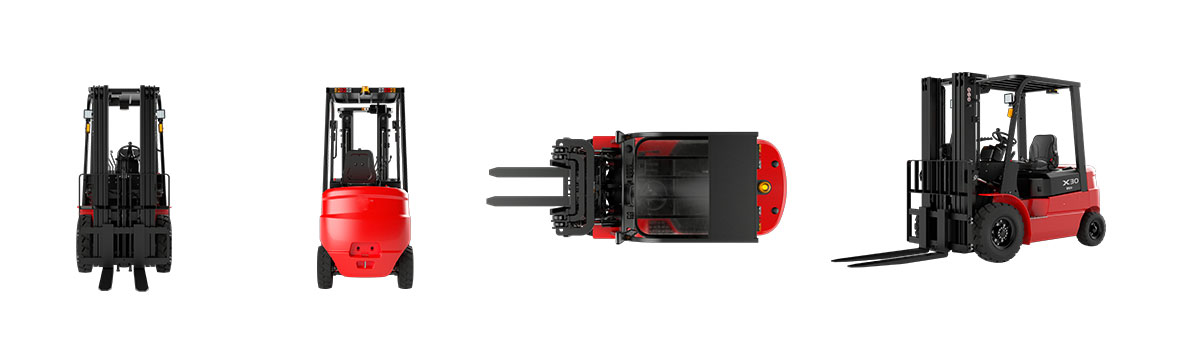

Product Detail

Technical Advantages

The lithium-ion forklifts stand out with cutting-edge technical innovations. At their core is the automotive-grade lithium battery paired with BMS (Battery Management System), enabling flexible power allocation—supporting 100AH, 150AH, and 230AH capacity options. The high-power permanent magnet motor delivers 15% higher energy efficiency than traditional motors, slashing energy consumption, while the integrated waterproof design (IP-rated connectors, instrument, and controller under the seat cover) passes standard rain tests, suiting both indoor and outdoor rough terrains. Smart connectivity is another highlight: HANDAVOS’s IoT system enables real-time monitoring of operating parameters, remote fault diagnosis via Bluetooth, and parameter adjustments through mobile devices, minimizing downtime for maintenance. Safety tech is comprehensive too, including optional active collision avoidance (automatic deceleration when detecting pedestrians), OPS system (preventing fork descent when the driver leaves the seat), and hydraulic explosion-proof protection—all enhancing operational security.

Production Process

Handavos adheres to strict manufacturing standards for the electric forklift . Key components undergo rigorous testing: lithium batteries are screened for 500+ charge-discharge cycles to ensure longevity, while permanent magnet motors go through 1,000-hour continuous operation tests to verify durability. The frame adopts a high-strength steel integral stamping process, with stress relief heat treatment to withstand heavy loads (3.0-3.2 tons) and reduce deformation. The instrument panel cover is made via one-piece stamping, providing robust protection for the multi-way valve and steering column. Every forklift undergoes 20+ quality checks before delivery, including load capacity verification, braking performance testing, and waterproof function validation—guaranteeing consistent reliability across each unit.

Application Scenarios

These forklifts excel in diverse scenarios. In large logistics warehouses, their 11km/h travel speed (full/empty load) and 3,000mm maximum lifting height optimize pallet handling and high-bay storage. For manufacturing plants (e.g., auto parts or electronics), the zero-emission lithium power suits indoor operations, avoiding exhaust pollution, while the compact design (1,154mm width, 2,217-2,250mm turning radius) navigates narrow production lines easily. Outdoor scenarios like construction material yards benefit from their 15% gradeability and high ground clearance, handling uneven surfaces without performance loss. They also fit e-commerce distribution centers, where the quick battery swap design (vehicle-battery separation) eliminates downtime, supporting 24/7 high-frequency operations.

Customer Cases

A leading Chinese e-commerce logistics firm adopted 50 units for its regional warehouse. Previously, lead-acid forklifts required 8-hour charging, causing 2-hour daily downtime; with this’s 15-minute battery swap, daily operation time extended by 3 hours, boosting cargo handling efficiency by 25%. A large auto parts manufacturer chose this forklfit for indoor assembly line material transport: its low noise (≤65dB) improved workshop environment, and the IoT system reduced unexpected breakdowns by 40%, cutting maintenance costs. For a construction material supplier’s outdoor yard, This forklift’s waterproof and terrain-adaptive design ensured stable operation even in rainy weather, reducing delivery delays by 18% compared to traditional diesel forklifts.