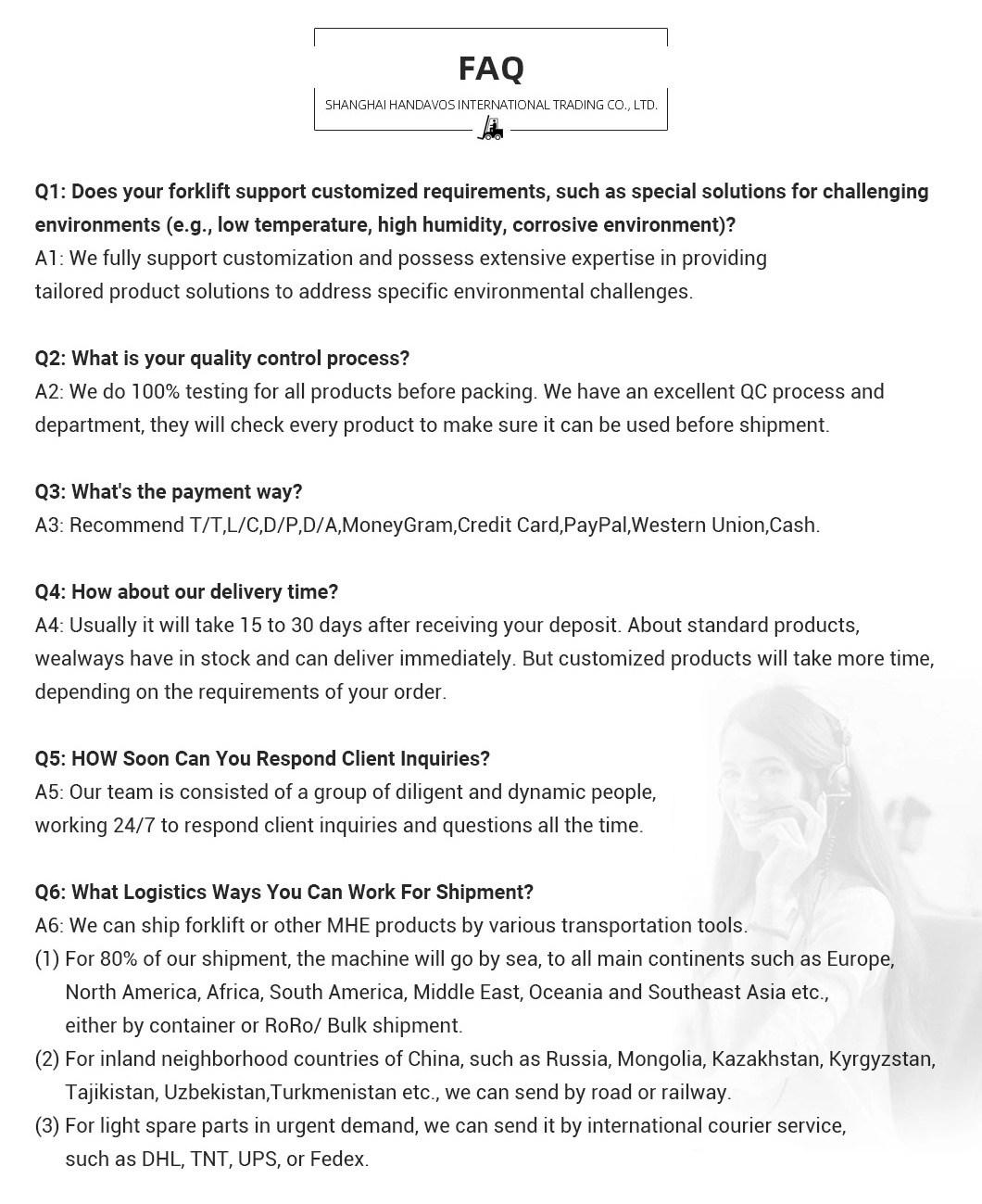

Product Parameters

Company

Shanghai Handavos International Trading Co., Ltd has been a trailblazer in the forklift and forklift spare parts industry for over a decade. Our state-of-the-art facility, sprawling across 30,000 square meters, is staffed by a dedicated team of 150 experts committed to excellence. Conveniently located in Kunshan, merely 100 kilometers from the bustling Shanghai Port, our strategic position ensures seamless logistics and transportation, reinforcing our leadership in the market.

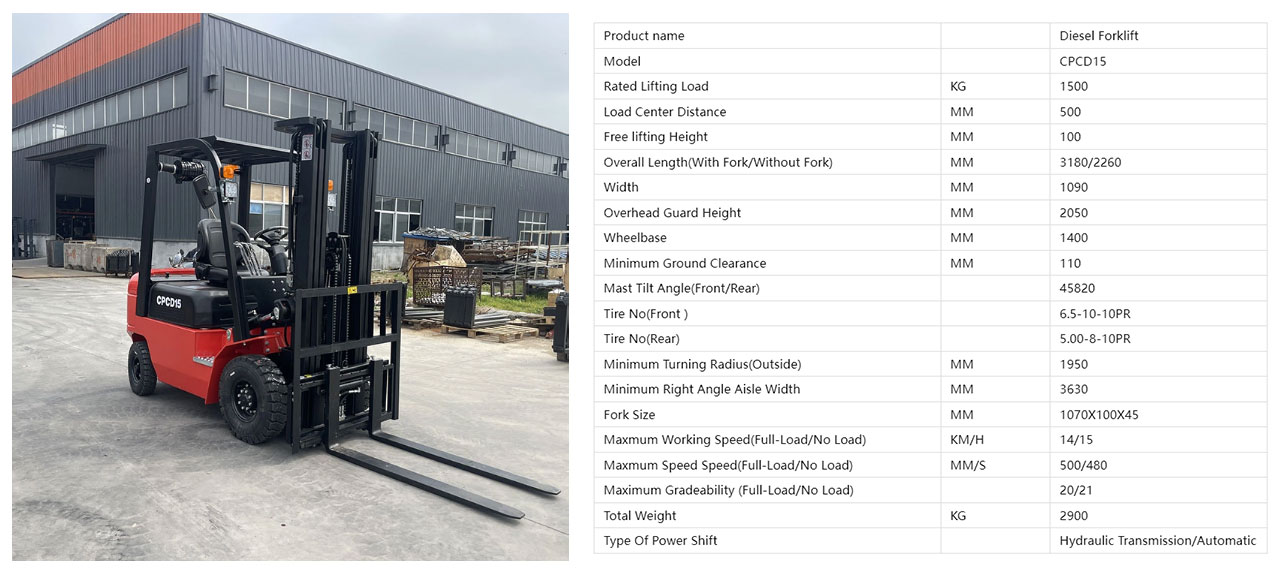

When it comes to our diesel forklifts, they boast remarkable technical advantages. Take the CPCD15 model as an example, with a rated lifting load of 1500 KG and a load center distance of 500 MM, it ensures stable lifting operations. The free lifting height of 100 MM allows for flexible maneuvering in confined spaces. Its overall length is 3180 MM with the fork and 2260 MM without, width is 1090 MM, overhead guard height is 2050 MM, wheelbase is 1400 MM, and minimum ground clearance is 110 MM, all contributing to a compact yet robust structure. The mast tilt angle (front/rear) of 45/20 degrees enhances operational flexibility. Front tires are 6.5 - 10 - 10PR and rear tires are 5.00 - 8 - 10PR, providing excellent traction and durability. The minimum turning radius (outside) of 1950 MM and minimum right - angle aisle width of 3630 MM enable smooth navigation in narrow areas. Fork size is 1070X100X45 MM, suitable for various pallet sizes. Maximum working speed is 14 KM/H under full - load and 15 KM/H under no - load, with maximum speed in MM/S being 500 under full - load and 480 under no - load, ensuring efficient material handling. Maximum gradeability is 20 under full - load and 21 under no - load, allowing operation on sloped terrains. Total weight is 2900 KG, and it adopts hydraulic transmission with automatic power shift for smooth and effortless operation.

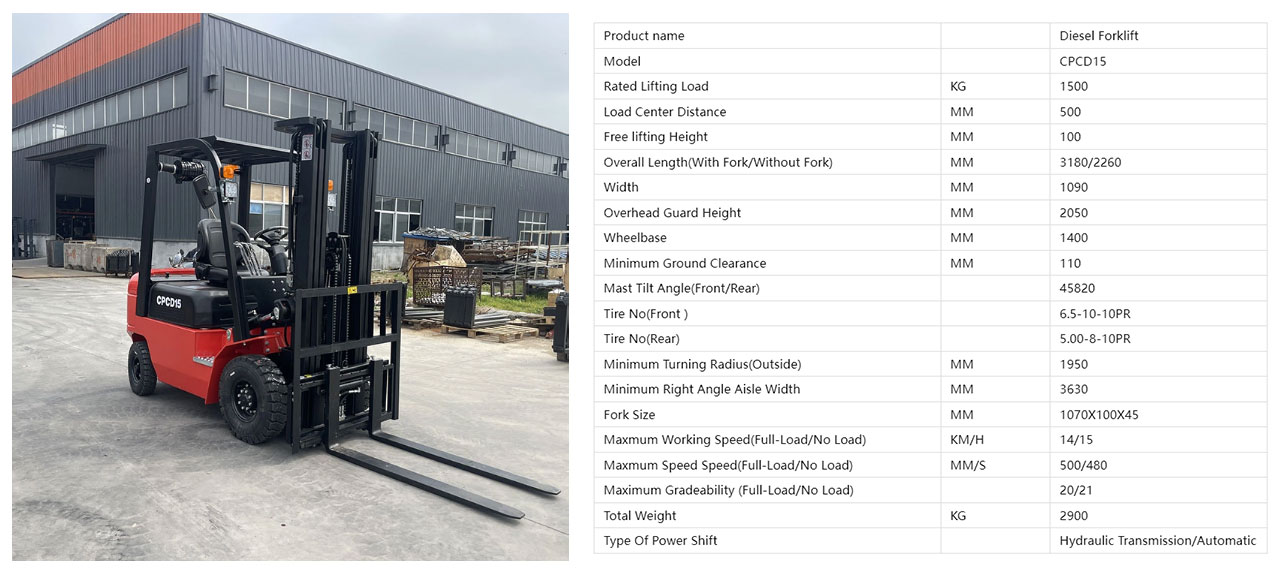

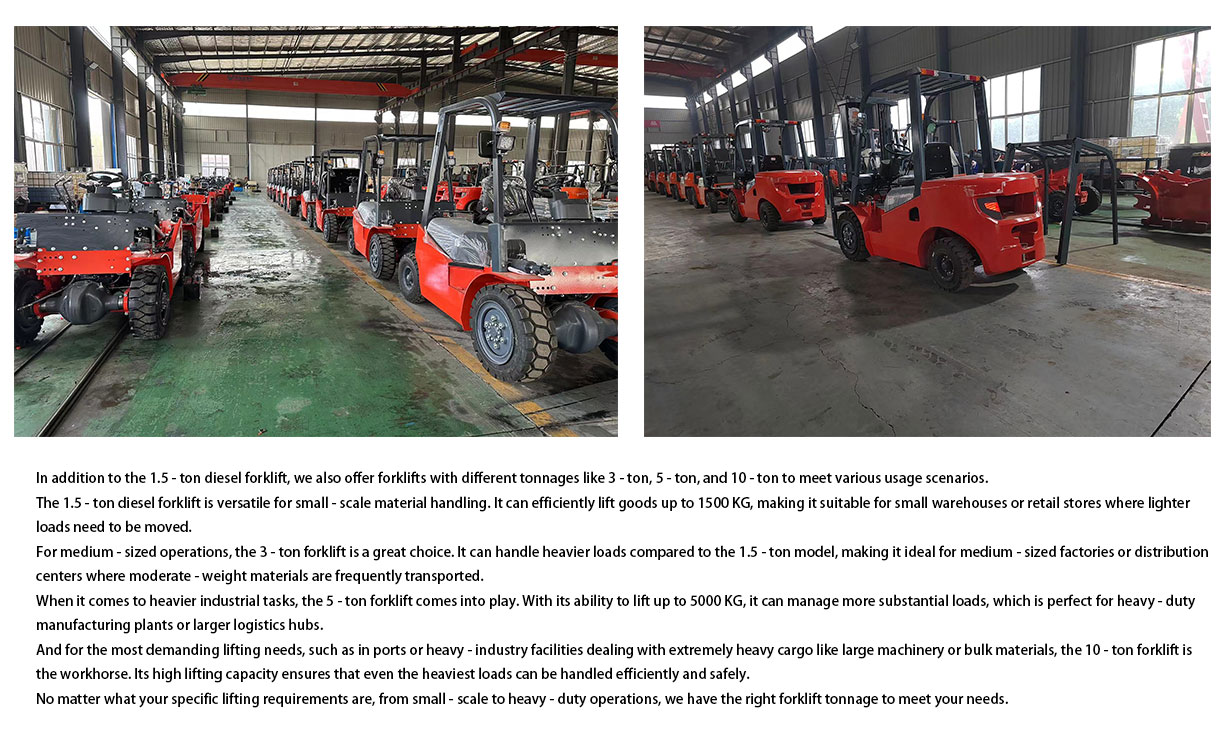

In addition to the 1.5 - ton diesel forklift, we offer a diverse range of forklifts with different tonnages such as 3 - ton, 5 - ton, and 10 - ton. The 3 - ton forklift is engineered for medium - duty tasks, with enhanced lifting capacity and stability to meet the needs of mid - sized warehouses and manufacturing plants. The 5 - ton model is built for heavier industrial applications, featuring a more powerful engine and reinforced chassis to handle substantial loads with ease. Our 10 - ton forklift is a heavy - duty solution, capable of tackling the most demanding lifting jobs in ports and heavy - industry facilities, with advanced suspension and control systems for precise and safe operation.

Our commitment to quality and innovation, combined with our extensive product range and strategic location, makes us the preferred choice for businesses seeking reliable and high - performance forklifts for various scenarios.

Maintenance Guidelines

1. Initial Oil Change: After the first 300 hours of operation, replace the differential gear oil, reducer gear oil, hydraulic transmission oil, and engine oil. Retighten all fasteners to ensure proper functioning.Re-tighten Fasteners: During the first 300 hours of use, re-tighten screws and tire bolts in all positions to ensure stability and safety.

2.Regular Component Maintenance: Follow the manufacturer’s guidelines to maintain the generator, controller, and battery group according to their specific instructions.

3. Connector Checks: Inspect all connectors of the forklift every 3 months to ensure they are secure and free from wear or corrosion.

4. Waterproof and Rust Prevention: Avoid using water guns for cleaning, and prevent exposure to rain to protect the forklift from water damage and rusting.

5. Door Frame Maintenance: Regularly clean the door frame by removing old lubricants and dirt, ensuring smooth operation of the forklift doors.

6. Battery Maintenance: Keep the battery surface clean and dry. Regularly check the battery water level and clean any accumulated dirt to ensure optimal battery performance.

7. Scheduled Maintenance: Develop a maintenance schedule based on working hours or months to ensure the forklift remains in good working condition throughout its use.